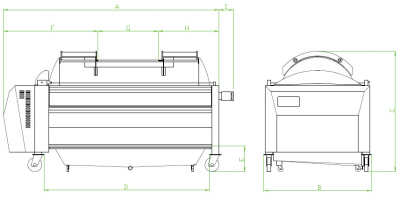

TPN ab 1600

Closed pressing-system TPN:

With the tank pressing system the juice is discharged by way of large sieve channels located on the inside. This design allows optimum juice drainage even with difficult types of must (e.g. red wine). Because of the large drainage surface, pressing times are achieved which are comparable with those of the open system. By selecting the timing of juice drainage, desired low-oxygen must fermentation can be conducted. Rapid removal of the interior sieves guarantees rapid cleaning.

- self-explanatory pressing program – operation via touchpanel

- different pre-programmed fixed programs

manual control or free progammable pressing programs, pectin-program,

whole grapes-pogram, flavour-programm, red-wine-program, primary-program „Grand Reserve“ - optional interface for external acess-uni e.g..: PC oder laptop

- Display of maintenance intervals and error messages

- Suggestions for troubleshooting on the display

- manual sliding door

- central filling

- Baskets cut at TPN 1600: 600 x 500 mm, 1 rectangular door slidable along the basket

- Baskets cut at TPN 2200: 870 x 500 mm, 2 rectangular doors slidable along the basket

- Baskets cut at TPN 2600 bis TPN 6000: 1070 x 500 mm, 2 rectangular doors slidable along the basket

- Baskets cut at TPN 7500 und TPN 10000: 980 x 500 mm, 1 rectangular door slidable along the basket

-

- external air-supply

- Clean-Manaell-Unit for easy quick-cleaning

- disc valve for controlled juice drainage

- Cooling jacket for the press basket

- Level control for juice tray

- external control

- PC-interface

-

- gravity funnels

- individual chutes

- sliding tubs

- custom-made overall plants

Open pressing-system PN:

In a cylindrical basket the pressing bellows presses the must against the perforated half of the basket (conical and depurred elongated holes) for unobstructed juice drainage.

Describtion

- Design completely in stainless steel

- hermetically sealed pressing programm

- Permanently mounted compressor and pre-pressure blower (also possible externally)

- Large geared motor (low-noise operation)

- Tight pneumatic door

- Frequenc controlles start-up

- Pressing membrane of polyurethane (suitable for foodstuff)

- Membrane exactly cut to size without creasing

- 3 filling programs (careful filling, fresh must, whole grapes)

- Pre-programmed filling position – loading from above

- Pre-programmed emptying position

- Free programmable cleaning position

- Easy cleaning

- Smooth pomace discharge

- Simple and quick cleaning because of fully welded parts